West Coast Label: Trusted Barcode Labels & Packaging Manufacturing for Business Since 1991

- 30+ Years of Barcode Label Manufacturing

- Engineered for Mission-Critical Scannability

- Rapid Turnaround Without Compromise

- Bring Your Creative Vision to Life

- Trusted by 5,000+ Satisfied Customers

- Expert Design & Production Support

- Experience the Quality – Free Samples & Quote

Barcode Labels by West Coast Label

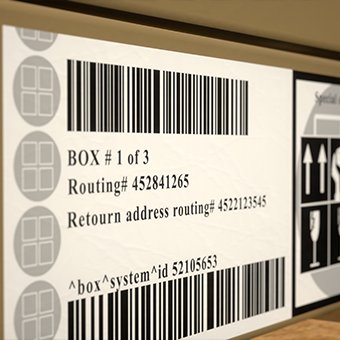

Protect your product’s identity with barcode labels built for extreme conditions. West Coast Label creates alcohol and solvent-resistant labels guaranteed to remain intact and legible. Get a reliable scan every time, from the production line to the end user.

Barcode Labels for Your Unique Brand

Explore our extensive range of label solutions tailored to various industries and applications:

Why Partner with West Coast Label?

Get a free physical proof. Approve your label before we print.

From design to delivery, we make it simple for you.

Smudge-proof and tear-resistant. Avoid costly reprints.

Our barcodes are precision-engineered for 100% scannability, preventing costly errors in your supply chain.

Precision printing you can trust, scan after scan.

Quick prototypes and on-time delivery to keep you on schedule.

Our labels are engineered for high-speed application lines, ensuring smooth production and minimal waste.

Flawless barcode performance that accelerates operations and eliminates costly errors.

Durable, Scannable Barcode Labels

Partner with West Coast Label for barcode labels engineered to perform. We deliver durable, scannable labels using sustainable materials and ISO 9001-certified processes, ensuring compliance and preventing costly reprints.

With over 30 years of experience, we provide a streamlined process from rapid prototypes to high-volume production, keeping your business on schedule.

Partner for Reliable Barcode Labels

Partner with our specialists to engineer barcode labels that meet your exact specifications for durability, adhesion, and scan reliability. Receive a physical proof for approval, ensuring optimal performance before production. Leverage our 30+ years of expertise to prevent scanning issues and ensure labels withstand your product’s environment.

Why Barcode Labels from West Coast Labels?

From complex GS1 specifications to standard barcodes, we deliver exact compliance.

We select substrates and adhesives that withstand moisture, temperature changes, and abrasion while maintaining perfect scannability.

Durable labels that prevent reprints, avoid compliance fines, and protect your operational timeline.

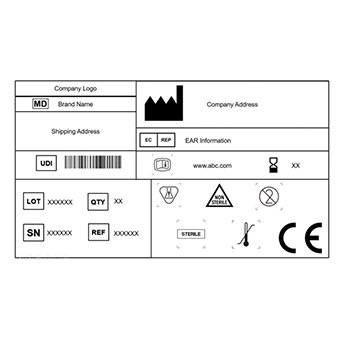

We make it simple. We primarily need:

- Your Barcode Data: The numbers you need to encode (e.g., GTIN/UPC, SKU numbers).

- Usage Environment: Where will the label be applied? (e.g., freezer, warehouse, chemical exposure).

- Surface Material: What is the label being applied to? (e.g., corrugated cardboard, plastic, glass, metal).

- Size & Quantity: Your desired dimensions and estimated annual volume.

We guarantee scannability through a combination of precision printing technology and rigorous quality control.

We use high-resolution printers that produce sharp, crisp edges on every barcode. Furthermore, we use professional-grade verifiers to test a representative sample from every production run against ISO standards, ensuring they meet the required grade for your industry.

Durability is our specialty. Based on your specific environment, we will recommend the right combination of specialized materials:

- Smudge-Proof Overlaminates: Protect against abrasion and moisture.

- Aggressive Adhesives: Ensure labels stay adhered in freezers or on challenging surfaces.

- Synthetic Materials: Use durable polyester or polypropylene films that resist tearing, chemicals, and extreme temperatures.

Absolutely. We have extensive experience producing labels that meet GS1, AIAG, and major retail requirements. We will work with you to ensure the barcode symbology, size, quiet zones, and human-readable text all comply with the necessary specifications, helping you avoid costly chargebacks and rejections.

Yes. While standard rectangles are most common, we can produce custom die-cut shapes to fit your product’s unique packaging or branding needs. We’ll guide you on how the shape can impact scannability to ensure optimal performance.

For standard materials, we offer rapid turnaround on both proofs and production. Prototype proofs are typically delivered within 2-3 business days. Full production timelines depend on quantity and complexity, but we prioritize efficiency to keep your operations on schedule. We provide a firm timeline with every quote.

You will receive a digital PDF proof for initial layout and data approval. For critical jobs, we highly recommend that a physical sample proof be mailed to you. This allows you to test the label on your actual product surface and verify scannability with your own equipment before full production begins.

Our difference lies in three key areas:

- Collaborative Expertise: We don’t just take an order; we partner with you to solve challenges before they happen.

- Proven Durability: Our labels are engineered to perform in real-world conditions, saving you from reprints and operational headaches.

- End-to-End Accountability: We manage the entire process from design to delivery, ensuring consistency and reliability you can count on.